1952 HUDSON HORNET TRANSMISSION REBUILD

THE KIRKLAND PROCESS

At Kirkland Transmission

we are well-versed on classic car restoration and transmission repair. We will work on any classic car transmission where others won't!!!

Classic and custom car owners are a special kind of owner. They are deeply attached to their vehicles and are interested in everything that happens to it.

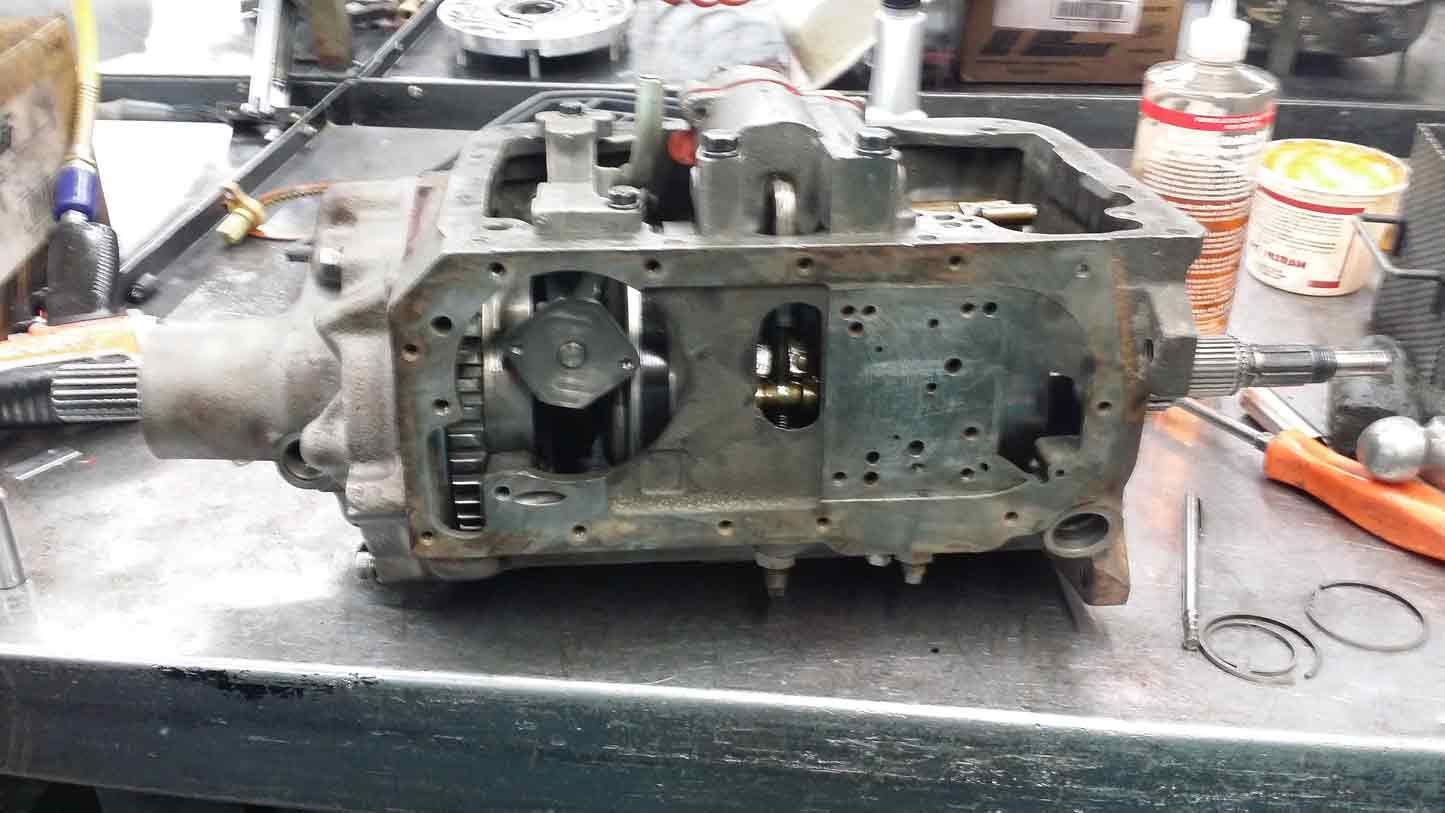

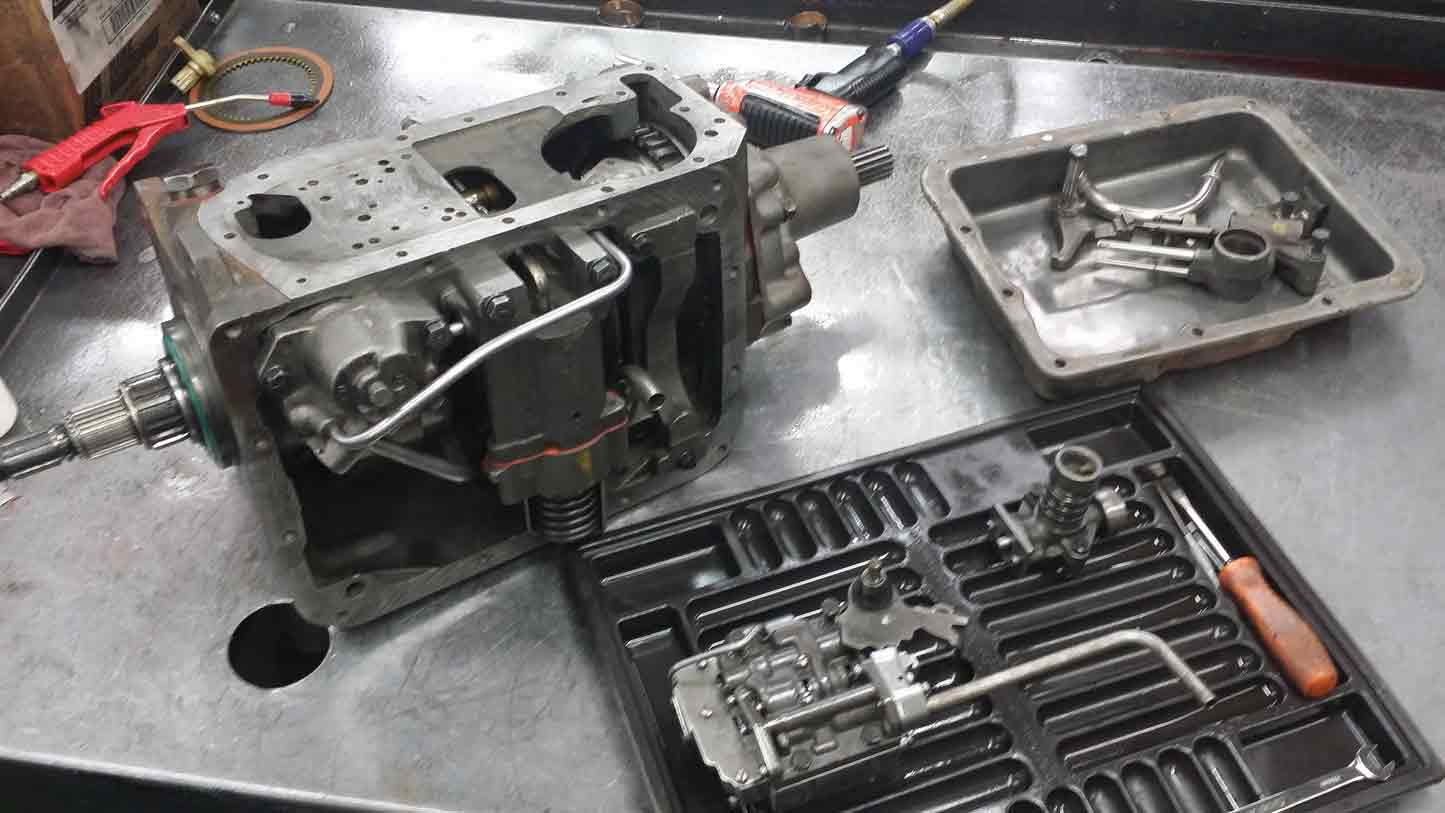

That's why Kirkland Transmission takes the extra step of providing them with progress photos during the rebuild process. It's our way of helping these special owners be a part of their own classic car restoration project.

Classic and custom car owners are a special kind of owner. They are deeply attached to their vehicles and are interested in everything that happens to it.

That's why Kirkland Transmission takes the extra step of providing them with progress photos during the rebuild process. It's our way of helping these special owners be a part of their own classic car restoration project.

LETTER FROM THE OWNER

"My experience with Kirkland Transmission was very satisfying. I appreciated how much attention Tony and Andy paid to my '52 Hornet Hudson. The bonus was receiving photos throughout the job to show me the progress. I would recommend their work to anyone."

Al Sjolander

Issaquah

March 2015

Al Sjolander

Issaquah

March 2015